electrical discharge machining adalah

Combining an absolute dedication to service and quality along with being entirely self-sufficient the Maroney Company can control the most complex projects from concept to completion. Electric discharge machining is a non-conventional machining process that uses an electric spark to remove metal from the workpiece.

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Checking the workpiece material and wire electrode.

. Machining and machine-tools 2013 View all Topics Download as PDF. Asal mula edm electrical discharge machining adalah pada tahun 1770 ketika ilmuan inggris joseph priestly menemukan efek erosi dari percikan arus listrik. EDM is especially well-suited for cutting intricate contours or delicate cavities that would be difficult to produce with a.

Dua proses utama yang termasuk dalam katagori ini adalah. Ad General Manufacturing LLC Delivers High-Quality Products To A Variety Of Industries. Electro discharge machining die sinking edm die sinking adalah proses pemesinan yang banyak digunakan pada benda kerja yang.

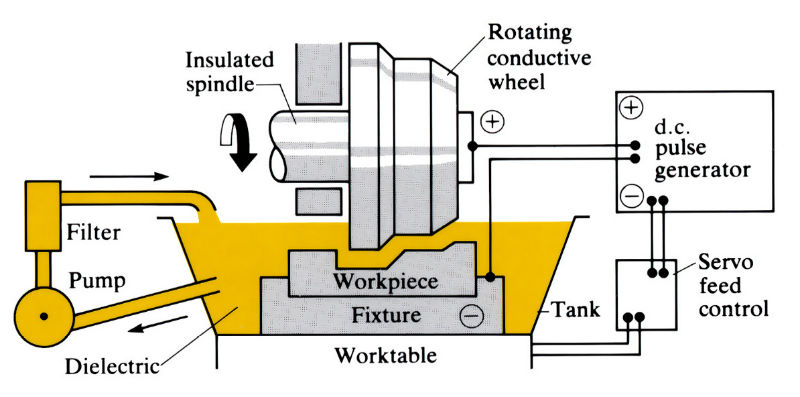

Typically the fluid is ionized water and the wire is brass or copper. Ad On-demand CNC machining with custom finishes and over 70 metal and plastic materials. The Basics of Electrical Discharge Machining EDM Wire Cutting Electrical Discharge Machining.

Catering to all aspects of. Asal mula EDM Electrical Discharge Machining adalah pada tahun 1770 ketika ilmuan Inggris Joseph Priestly menemukan efek erosi dari percikan arus listrik. Asal mula EDM Electrical Discharge Machining adalah pada tahun 1770 ketika ilmuwan Inggris Joseph Priestly menemukan efek erosi dari percikan arus listrik.

Electrical Discharge Machine EDM adalah suatu mesin perkakas Non Konvensional yang proses pemotongan material material removal benda kerjanya berupa erosi yang terjadi karena adanya sejumlah loncatan bunga api listrik secara periodik pada celah antara katoda pahat dengan anoda benda kerja di dalam cairan dielektric. EDM dapat digunakan pada bahan yang konduktif. Our Services Include CNC Machining Grinding Milling EDM Wire Water Jet Cutting More.

Ad At Surplex you will find used machinery and industry equipment at best prices. Strong easy to machine great surface finish isomolded graphite. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by.

MILCO Wire EDM an AS9100 and Nadcap Certified EDM services provider offers top quality electrical discharge machining services and has been the industry leader since 1990. Precise and Affordable EDM Services. Be sure you will get the best out of more than 4000 used machines and tools.

We offer many services and products including wire electrical discharge machining services EDM hole popping EDM hole drilling EDM hole drilling equipment metal parts cutting tools EDM hole burners stamping dies automotive components precision machining extrusion tooling injection mold large hole drilling small hole drilling and more. Pada saat proses pemotongan akan muncul uap logam yang sangat kecil pada wilayah erosi. This is a manufacturing operation in which we.

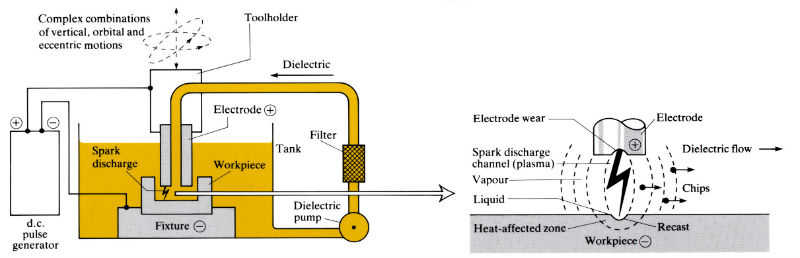

The process includes an electrode and a workpiece- both submerged in a dielectric fluid. Listrik mengalir di antara elektroda dan benda kerja dalam cairan dielektrikum. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid.

This process is done by applying high-frequency current through electrodes and Workpiece emerging in the dielectric fluid. With capabilities of Wire EDM Small Hole EDM Drilling Conventional Sinker EDM and Water-jet services. Founded in 1955 the Maroney Company is among the most sought-after unique ultra-precision machining companies in the world.

Electrical Discharge Machining EDM is a method for producing holes and slots or other shapes. For this type of EDM a wire is used as an electrode and is continuously and automatically fed with a spool during the process. AS9100 ISO 9001 Certified.

It is also known as Spark erosion Electro-erosion or spark machining. Electrical Discharge Machining or more commonly known as EDM is the method of creating complex shapes in hard materials with the use of electric current discharges. Quality CNC machined parts delivered on-time at consistently low prices.

For Precise Machining and Remarkable Surface Finish. Electrical discharge machining EDM is a commonly used manufacturing process for creating slots eyelets grooves and cut-offs in processed parts. Rapid electrical current passes between the workpiece and the electrode.

It is also called spark erosion. Electrical Discharge Machining EDM adalah proses pemotongan logam yang dilakukan dengan penciptaan ribuan kotoran per detik.

Pudak Scientific Aerospace And Precision Part Machining

Mechanical Engineering Electrical Discharge Machining Edm Principles

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Ch 26 Abrasive Machining And Finishing Operations Brenton

Electrical Discharge Machining Itu Apa Sih Pt Indonesia Surya Sejahtera

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Grinding Edm Grinding Electric Discharge Machining Professor Sujin

Edm For Injection Mold Building Basilius Inc

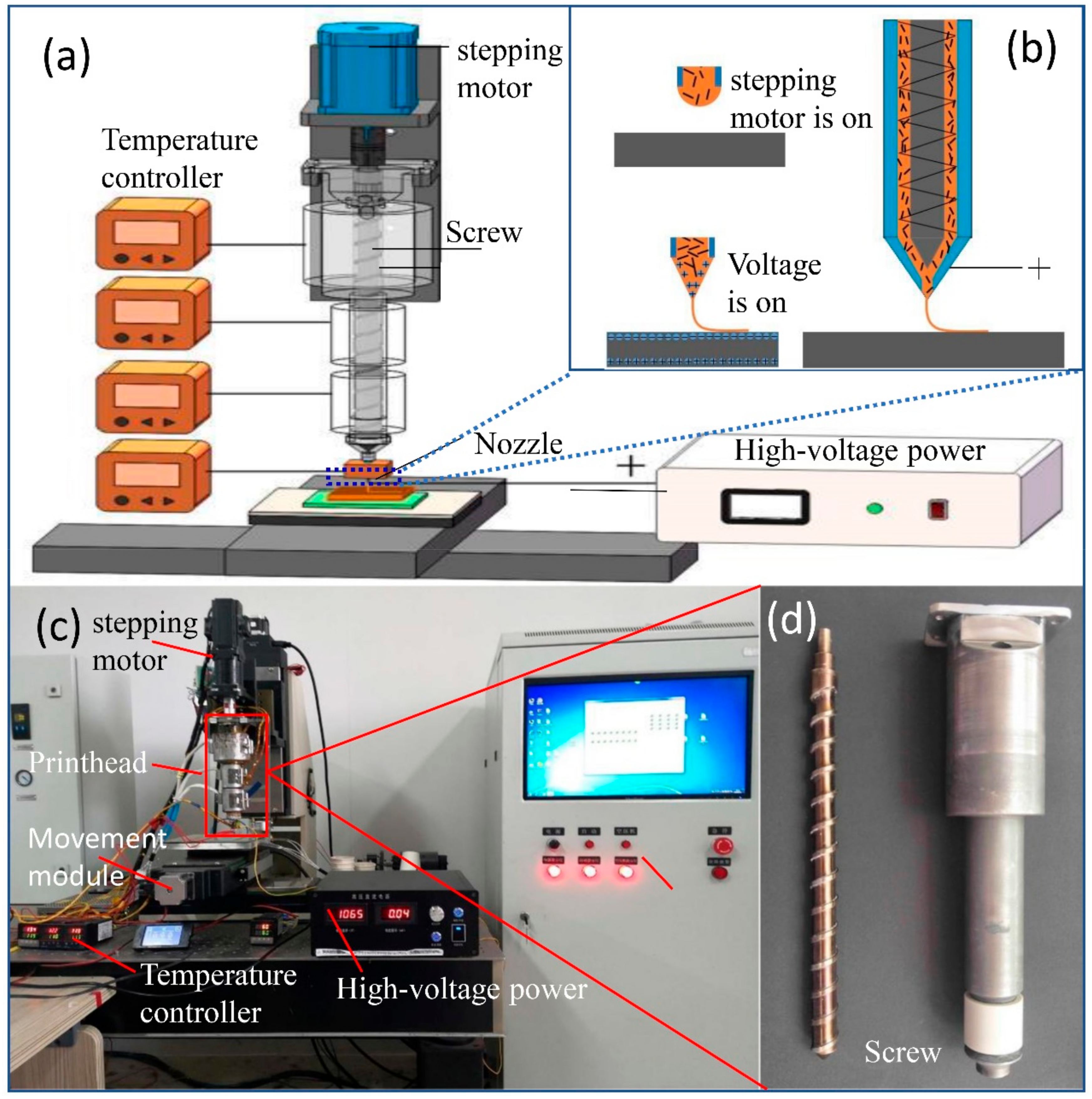

Micromachines Free Full Text The Electric Field Driven Fusion Jetting 3d Printing For Fabricating High Resolution Polylactic Acid Multi Walled Carbon Nanotube Composite Micro Scale Structures Html

Gambaran Singkat Edm Hari Pernanda Lukman Academia Edu

Pdf Die Sinking Edm Process Parameters A Review

Edm Notches Custom Applications Top Notch Edm Services

Cnc Wire Cut Edm A And Experimental Set Up B Download Scientific Diagram

Schematic Diagram Of Electric Arc Discharge Apparatus Download Scientific Diagram